This step of washing is as essential with regards to quality and the health stakes that processing food products represents. Destoning and washing use water to separate and wash the products of any foreign body that could still be entwined therein. Destoning is done upstream of washing and, due to the hydraulic process, carries out a pre-washing with a water circuit different from that of washing in order to improve the performance of the latter. FEMIA is well-known worldwide for its efficient and compact solutions for destoning and washing.

Destoning through extraction or water flow, dedicated or universal washers, we have developed many solutions for destoning and washing floating and sinking products. We offer options according to needs (insect traps, for example). Combining performance and robustness, FEMIA equipment is recognised in the market for its quality and longevity.

Always very attentive to your performance and our impact on the environment, we have integrated a rotating wire filter which, placed on the water return circuit, filters and recycles the water in a closed loop on each machine. This makes it possible to adopt a more responsible approach while still benefiting from undeniable savings in resources and energy.

Femia's engineering office will provide you with support for customised processes

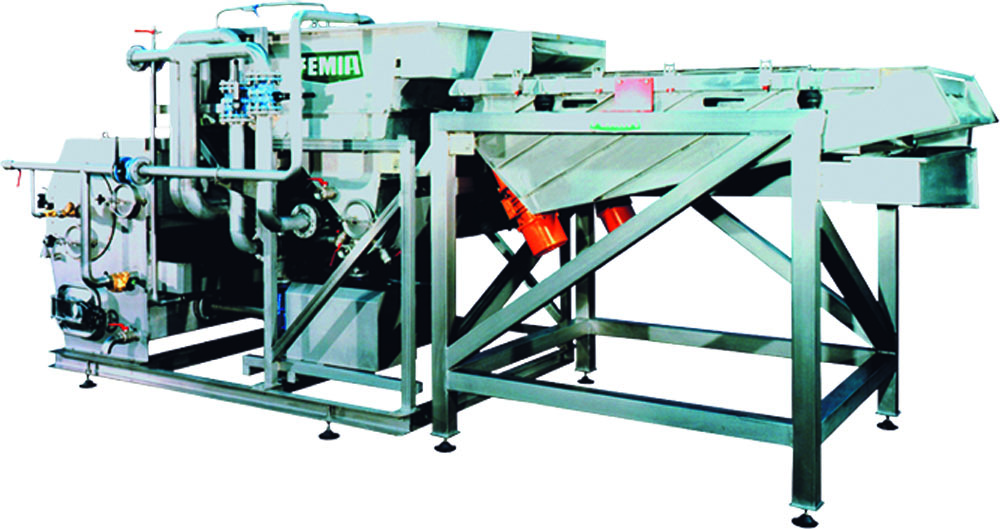

Examples of solutions dedicated to destoning and washing

Femia Industrie has developed various specific solutions for destoning and washing. Whatever your project may be, we have the adequate solutions. Discover our dedicated machines:

EC1x

-Separates the elements that are denser than the processed product.

-Suitable for most vegetables.

-Capacity: 5 t/h to 20t/h according to the unit weight of the products processed and the model.

-Machine comprised primarily of a tapered tank with a blade system that allows for the creation of a vortex in the tank, a pump that allows for the sustentation of the processed products and a system for water recovery.

-Water recovery and filtration via a modular plate belt or a vibrating drainer and a settling tray.

-Circulation of water in a closed loop for low water consumption.

-Removal of waste thanks to a stone lifter or a chamber with 2 controlled valves and its control box.

EH3x

-Extracts the waste that is denser (stones, clumps of soil, various objects etc.) than the processed product.

-Capacity: 12 t/h to 15t/h according to the model.

-Machine primarily comprised of a destoning tank, a pump that allows for the sustentation of the processed products and a vibrating draining separator.

-Recovery in a settling tray under the separator and filtering of the water with a wire screen.

-The upper screens of the vibrating separator can be removed and are perforated according to the product processed.

-Continuous removal of heavy waste in a chamber with 2 controlled valves and its control box.

LM/P1x

Washes non-floating granular products (peas, maize, beans, flageolets, borlotti, chickpeas, etc.) and separates them from floating waste (skins, damaged grains, miscellaneous waste).

– Capacity: 3t/h to 20t/h depending on the model and the product treated.

Machine mainly made up of a swan-necked washing tank, pumps that allow the creation of turbulent flows and a vibrating dewatering separator. The upper grids of the vibrating separator are removable and perforated according to the product treated.

-Recovery of water in a settling tank under the separator and filtration of the water with a rotating wire drum and its scraper in order to separate the waste.

-Closed circuit water circulation for low water consumption.

-The washer is fed either by a stone removal belt (included in the price of the LPx washer) or a vibrating separator (not included in the price of the LMx washer).

Lx

-Washes most vegetables.

– Capacity: 5 t/h to 15t/h depending on the model and the product treated.

– Machine mainly made up of a washing tank, pumps that allow the creation of turbulent flows, a paddle turnstile to ensure the progression of floating vegetables and a lift belt.

– Recovery of water in a settling tank at the outlet of the washer and filtration of the water with a rotating wire drum and its scraper to separate the waste.

– Closed circuit water circulation for low water consumption.

– Depending on the products treated, a paddle turnstile can be replaced by an insect trap.

– As an option, a datura trap can be integrated into the washer.

LEx

-Special for spinach.

-Capacity: 2.5 t/h to 8t/h according to the model.

-Machine comprised pre-washing and washing tanks, pumps that allow for the creation of turbulent flows, some insect trap and propeller to make the leaves plunging in the turbulent bath.

-Recovery of the water in a settling tray at the outlet of the washer and filtering of the water with a wire rotating drum and its scraper in order to separate the waste.

-Circulation of water in a closed loop for low water consumption.