Regardless of the nature of the product processes, cleaning and sorting are essential steps in the production process, its yield, hygiene and food safety for consumers. This more or less complex step is necessary for the removal of foreign bodies and requires a high capacity to adapt which requires having machine in cascade that are suitable for removing a maximum amount of waste as early as possible in the preparation line.

We have developed various dry cleaning and sorting solutions so as to handle your specific problems. Thus, according to the nature of your products, their condition as they leave the field and the foreign bodies linked to the farming areas (sand, soil, rocks, wood, small animals, various foreign bodies, etc.), we adjust the cleaning process by choosing the right equipment in order to remove foreign bodies, poor-quality products and any pollutants.

Drums, fans, separation vibrators… our dry cleaning solutions are designed for optimum yield and constant product quality. Aware of the importance and the stakes of this step, we innovate and continue to develop state-of-the-art cleaning systems. That is how for example we designed a Datura trap. Installed upstream well ahead of the process, it allows for the removal of this toxic plant that has a significant health risk.

Femia's engineering office will provide you with support for customised processes

Examples of solutions dedicated to cleaning and sorting

Among our wide range of machines devoted to cleaning and sorting, we will determine together the one that best suits your needs. Discover our cleaning and sorting range:

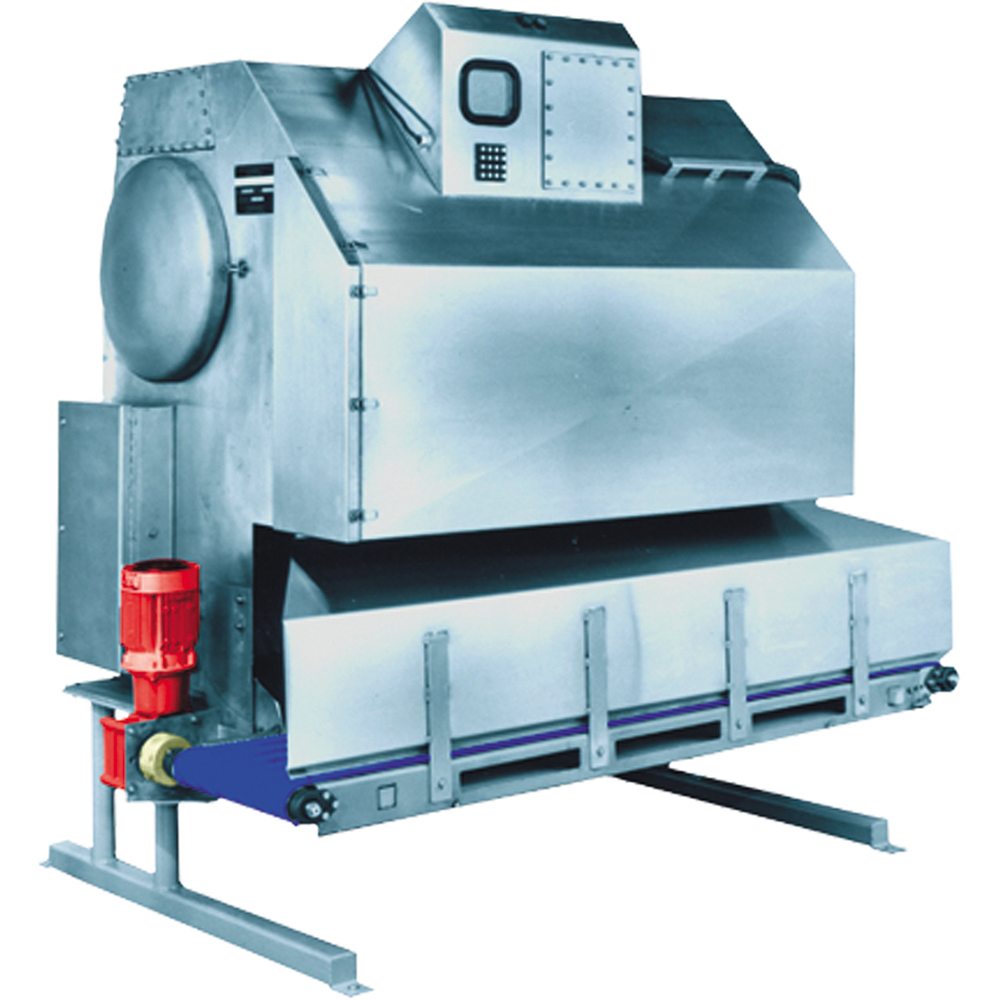

TN1x

-Installed at the inletof the line for granular products such as peas/flageolets, it removes small waste, sticky waste as well as large waste.

-Capacity: 8 t/h to 20 t/h depending on the unit weight of the treated products and the model.

-Machine mainly consisting of a drum whose perforations in the final section are adapted to the product being treated.

-Continuous cleaning of the machine thanks to its system of brushes and scrapers.

-Exit of the products to be treated under the 3rd section of the drum.

-Recovery and evacuation of waste thanks to a belt conveyor placed inside the drum (except for small waste at the beginning of the machine).

S3x

-Extracts the small long-shaped pieces from the flow of green beans.

-Capacity: 500 kg/h to 3 t/h according to the model and the calibre of the green beans.

-Vibrator comprised primarily of a vibrating pan with aligning corridors and holes with a length that can be adjusted as well as upper screens.

-Also separates small heavy waste and gravel.

-Optional perforated upper screens according to the characteristics of the sorting to be carried out.

S5xB

-Continuous draining on all product types.

-Capacity: 3 t/h to 20t/h according to the unit weight of the products processed and the model.

-Vibrator comprised primarily of a vibrating pan with removable and perforated screens according to the dimensional characteristics of the products processed.

-The optional spillway at the inlet of the vibrator allows for the recovery of products coming from a hydraulic carrier.

GCE (CCM)

-Separates unhusked ears of (green) corn from the flow of products.

-Capacity: 14 t/h to 50t/h of yellow corn according to the model.

-Machine primarily comprised of a feed vibrator, an optical sensor and deflector flaps allowing for the ejection of unhusked ears of corn on a transversal output belt as well as a control box with PLC.

SP3x

-Removes and sorts small pieces of long-shaped products of the green bean, carrot, salsify, etc. type.

-Capacity: 2 t/h to 5t/h according to the unit weight of the products processed and the model.

-Machine comprised primarily of a drum fitted with plastic pockets and a conveyor inside the drum to collect the small pieces from the flow of products.

-Different pocket diameters are available according to your needs.

-The machine is continuously cleaned thanks to its system of brushes and CIP(clean in place ).

S4x

-Separates the free beans from the mechanically harvested green bean clusters.

-Capacity: 8 t/h to 12t/h according to the unit weight of the products processed and the model.

-Machine primarily comprised of a drum fitted with hooks of special shape.

-Mobile machine mounted on rollers so that the position of the drum can be adjusted in relation to the fall of products above the drum.

S33x

-Separates unsnipped green beans from the flow of green beans.

-Capacity: 1 t/h to 3t/h according to the unit weight of the products processed and the model.

-Machine comprised primarily of a drum with louvered slots, a rotating blade system and a conveyor inside the drum to collect the unsnipped green beans.

-At the outlet removal of the unsnipped green beans on the dedicated belt and snipped green beans on another belt.

-A continuous cleaning of the machine.

TLMx/Px

-Separates large waste from granular products, such as peas, flageolet beans and sweet corn and provides continuous and even distribution of the processed products to a downstream machine.

-Capacity: 3 t/h to 20t/h according to the unit weight of the products processed and the model.

-Vibrator comprised primarily of a vibrating pan with removable and perforated screens according to the dimensional characteristics of the products processed.

-An additional option for draining/water recovery using perforations on the bottom of the pan and a hopper under the pan.

S2x/VE05

-Removes small waste (sand, soil, small plant waste) from various different products (green beans, spinach, leafy vegetables).

-Capacity: 3 t/h to 8t/h according to the unit weight of the products processed and the model.

-Machine comprised primarily of a drum that can be adapted according to your products.

D20 / D21

-Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. -Capacity: 8 t/h to 20t/h according to the unit weight of the products processed and the model.

-Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed.

-Continuous cleaning of the machine thanks to its system of brushes and scrapers.

-Products to be processed exit from the 3rd section of the drum.

-Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

EB11

-Depods hand-harvested pods.

-Capacity: 3t/h of pods which produce an average 1.3 t/h of peas (depends on the quality and the maturity of the pods).

-Machine formed primarily from two concentric drums comprising 12 bats on the inner drum and 16 counter-bats on the outer drum.

-Extraction of the pods and light waste from the flow of products thanks to an inclined belt under the double drum.

-Easy to clean thanks to its three removable screens.

-Cleaning system that allows for continuous operation.