This step represents a particular stake with regards to classifying products. Indeed, the diversity of shapes of the vegetables and formats desired at the outlet of the preparation line requires having available and choosing the right equipment in order to obtain the required product categories.

Our offer is comprised of effective solutions that are particularly suitable for working with different types of fruits and vegetables. This step in the process is the critical step for the material yield of the preparation line. We thus propose various cutters that are especially suited for cutting corn but also cluster cutting, snipping and cross-cutting of green beans.

FEMIA has developed calibration solutions, which correspond to the particular requirements of the various types of vegetables. Femia drums and vibrators accurately select and class processed vegetables according to their size and can be adjusted in order to correspond precisely to the calibration standard sought.

Effective and fully adaptable, our customised solutions, with different levels of automation, are intended to optimise as much as possible the yield and the profitability of your line.

Femia's engineering office will provide you with support for customised processes

Examples of solutions dedicated to calibration, preparation and cutting

Discover our range of solutions for preparation and cutting. According to your needs, we will suggest the machine or machines that are most suited:

C32

-Cross-cuts long

-shaped products (<20cm) into 26, 32, 39 or 52 mm pieces.

-Capacity: 2t/h to 3t/h according to the model and the product processed.

-Machine comprised primarily of an aligning vibrator and of a cutting head comprised of two straight-blade rollers.

-Excellent straight cutting regularity thanks to a vibrating system that aligns the processed products.

-Tilting system of the cutting head for adjustments and maintenance.

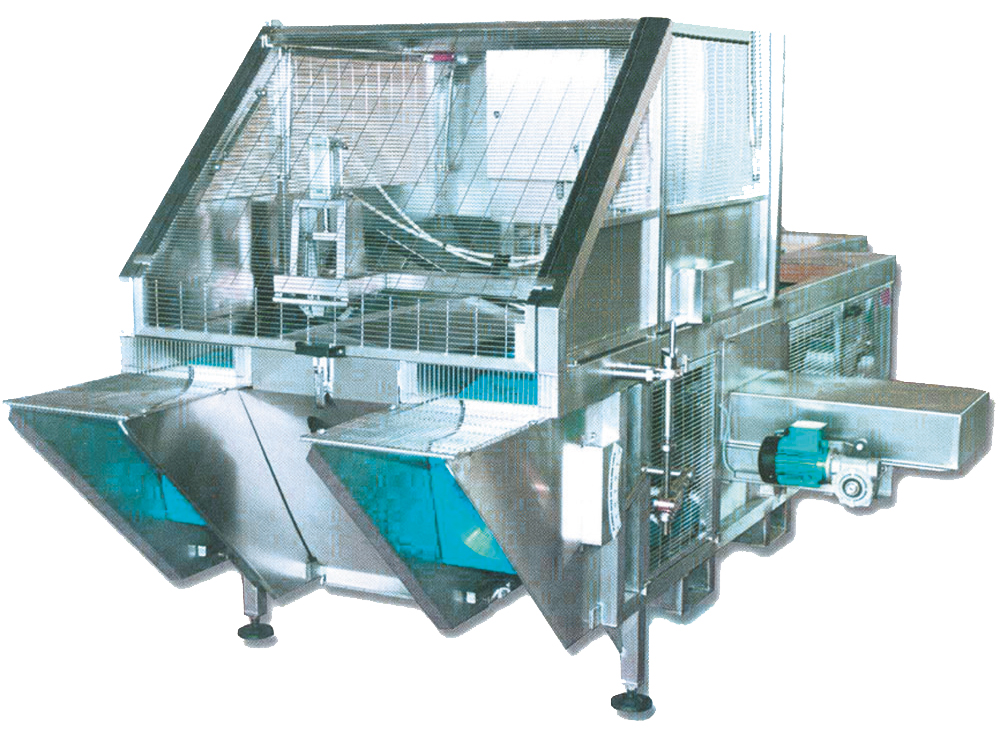

ACC (CCM)

-Cuts husked ears of corn.

-Capacity of 110 ears/minute.

-Machine primarily comprised of a feeder belt and a rotating bowl that allows for transfer of cobs on a corn belt one after the other and correctly aligned, of an automatic “head first” orientation system of the ears and of a cutting head comprised of 6 blades arranged like a diaphragm of a camera.

-The orientation system is also capable of “diverting” ears that are too short.

-Self-clearing of the cutter head is case of jams.

-The cutter requires the dedicated WKS blade sharpener.

CCM

-Cuts husked ears of corn.

-Capacity of 60 ears/minute (according to the performance of the operator who is feeding the cutter).

-Machine primarily comprised of a cutting head with 6 blades arranged like a diaphragm of a camera.

-Self-clearing of the cutter head in case of jams.

-The cutter requires the very specific WKS blade sharpener.

CCM

-Saws the husked ears of corn into several pieces (1 to 3).

-Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter.

-Capacity (manual feeding version) of 60 ears/minutes with two operators.

-Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt

-Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

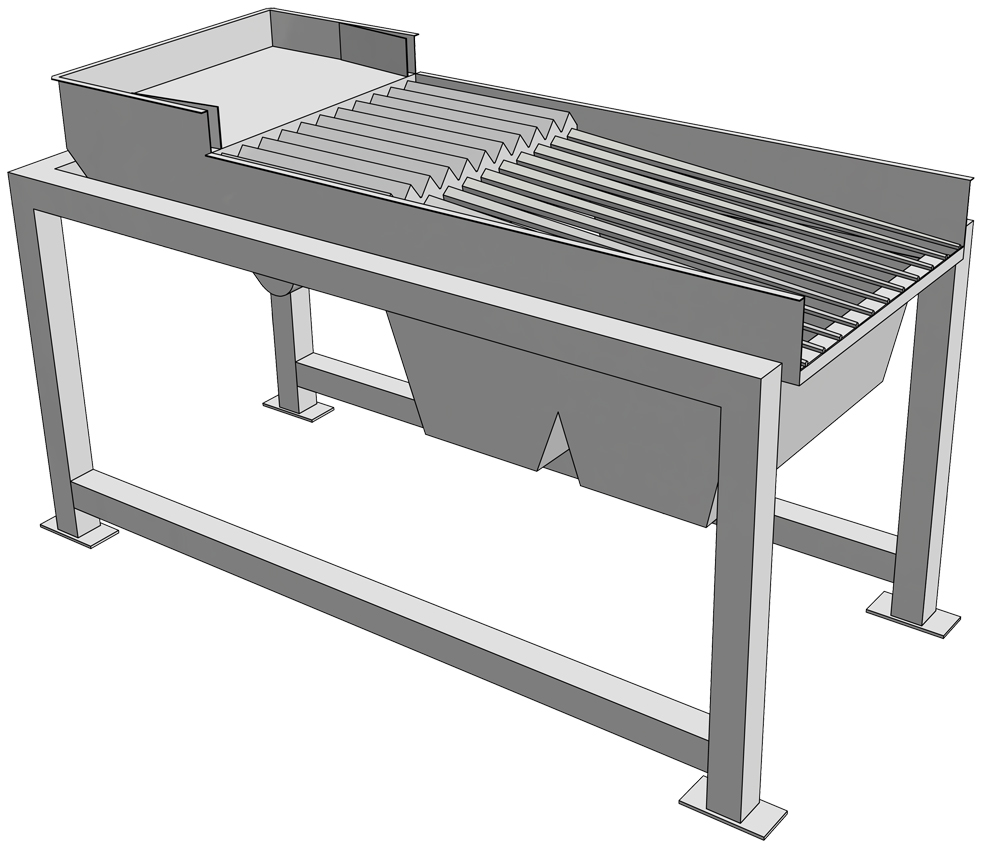

A&K

-Pulls off the husks of unprocessed ears of corn.

-Capacity: 4 t/h to 16t/h according to the model and the product processed.

-Machine primarily comprised of a roller table, a vibrating feeder and of a variable-speed conveyor with its hopper in the upper portion.

-The roller table is comprised of 4, 8, 12 or 16 “Lanes” keeping in mind that a “Lane” comprises 2 axes with rollers.

-Range of various husker rollers according to the variety of corn processed

-Regular feed thanks to a variable-speed conveyor belt and a vibrator that aligns the ears before the roller table.

-Recovery of the husk and silk waste under the roller table.

C1x

-Sorts granular products (peas, flageolet beans, etc.) by calibre (XF, TF, F, Medium for peas).

-Capacity: 7 t/h to 18t/h according to the model and the product processed.

-Machine comprised primarily of a rotating drum with perforated plates and corresponding hoppers

-Length and diameter of the drum are customised according to the characteristics of the processed product and the calibres sought.

-Continuous clearing of the drum thanks to a scraper system.

-Possibility of adding belt conveyors and intermediate storage hoppers.

E6x

Cuts the ends of the green beans or products of similar shape,

-Capacity: 300 kg/h to 3t/h according to the model and the product processed.

-Machine primarily comprised of a drum with wave-slots plastic segments for a clean and precise cut of the ends of green beans.

-Large range of plastic wave-slots segments (slot width is to be selected according to the calibre of the green beans processed).

-Optional safety guards and cleaning in place system.

T4x

– Sorts green beans in diameter into 2 sizes: the smaller ones come out under the drum, the larger ones at the end of the drum.

-Its unique, high-performance design allows the full release of the smaller diameter green beans between the sorting bars.

-A very precise range of settings ensures product homogeneity, especially on extra fine sizes.

-The T43L and T46 models sort green beans into 2 sizes.

-The T44 model sorts in 2-3 sizes.

-For better user comfort, the T46 can be equipped with a remote adjustment system.

DECORA (MHME)

-Removes the cores from cauliflower or broccoli while creating florets

-Capacity of 120 heads/minute.

-Machine primarily comprised of a conveyor belt feed, two symmetric lines (belts with cups, cutting head, outlet elevator) and a waste extraction elevator.

-Height-adjustable cutting head. A single-lane Decora with a capacity of 60 heads/minute is also available.

T6x

-Sorting and calibrating of products such as strawberry/lemon/flower cabbage with 4 sizes.

-Mobile product thanks to its 4 removable feet.

-The vibrating unit is designed to eliminate small product breakages and allow ideal spreading of the products.

-A hopper under the vibrating element is adjustable to adapt to 4 calibers of your products.